Global operation for automotive headrest parts

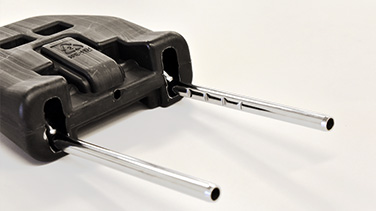

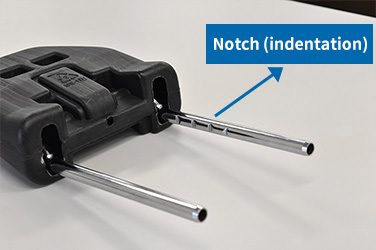

The Industrial Supply & Infrastructure Division is focusing its efforts on the manufacture and sale of automotive headrest stays. It operates globally and has constructed a supply system that features high cost-competitiveness in order to meet customer needs for high quality and greater added-value. Group companies such as NST ARAI Automotive Co., Ltd. Ltd. and JR Manufacturing, Inc. are focusing on the manufacture of headrest stays, and are refining their only-one technologies and aiming for the top share of the global market. In addition, we are working to improve both headrest safety performance and comfort through the development of a press notch method*1 that is able to reduce weight by using thinner pipes than are possible with the notch cutting*2 method, and through the development of headrest stays that include mechanical components. The Industrial Supply & Infrastructure Division has also created a Global Headrest System Team (GHS Team) and is working together with Group companies and utilizing our network in Japan and overseas for global supply of highly advanced headrest parts that deliver higher value. At present, the headrest parts produced by the Group control an estimated 13% global share of the market. However we are aiming to become a Global Niche Top Company and have set a target of 17% market share for 2020.

- *1The press notch method is a method of forming notch parts by pressing. Because the pipe thickness at the notch part does not change after pressing, it is possible to maintain the headrest stay strength. It is also possible to use thinner pipes to reduce weight.

- *2The notch cutting method forms the notch by cutting away the material at the notch position. The pipe thickness at the location of the notch is reduced after cutting. In order to lack of strength, the notch cutting method requires thicker pipe, which makes the products heavier.