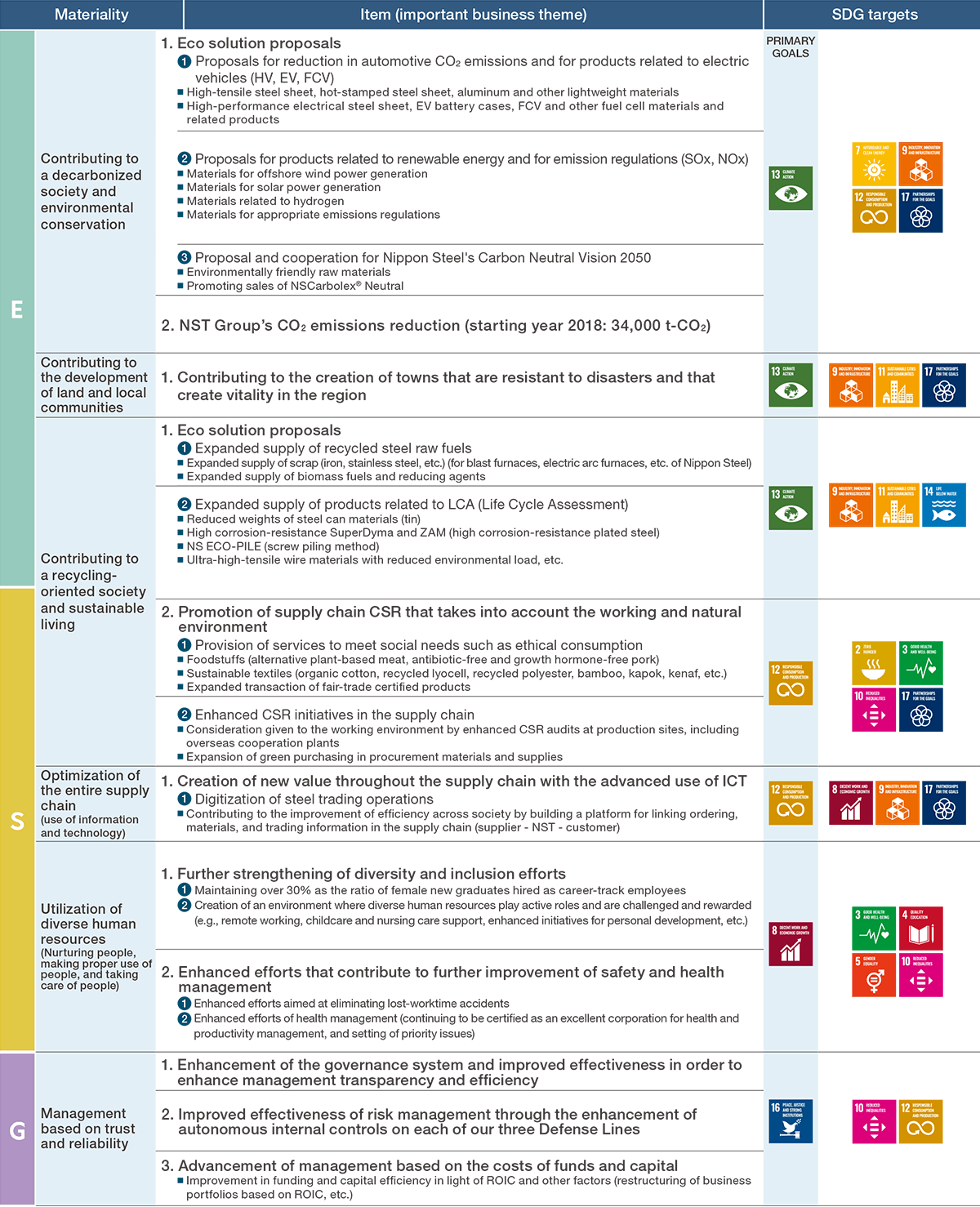

Initiatives and KPIs to Address Priority Issues (Materiality)

In order to contribute to the realization of a sustainable society, the NST Group has identified six priority issues (materiality) related to ESG management that must be focused on, based on the issues of stakeholders, the Group’s corporate philosophy and roles, and growth strategies.

Initiatives related to these issues will lead us to the achievement of SDGs corresponding to each of the materiality components we identified. Recognizing the role that our stakeholders and society expect us to play, we are actively working to resolve the issues and achieve the SDGs.

Each division selects priority themes to address and creates a detailed action plan, which it then carries out. The Sustainability Committee also conducts regular monitoring of progress and operates a PDCA cycle in connection with the business strategy to reliably achieve results. We will utilize key performance indicators (KPIs) that evaluate the results from efforts to address materiality to conduct proper follow-up and ensure full implementation, thereby contributing to sustainable social growth and enhancing corporate value.

Sales expansion and construction of a supply chain for steel materials used in the foundations of offshore wind power generators

On the way to creating a zero-carbon society

Working to expand offshore wind power generation

In the area of offshore wind power generation where installation is expected to grow in the future, large amounts of steel materials are used in the towers, foundation parts (jackets, monopiles), substations, and other parts. NST is focusing on expanding sales and constructing a supply chain for the steel plates used in these applications.

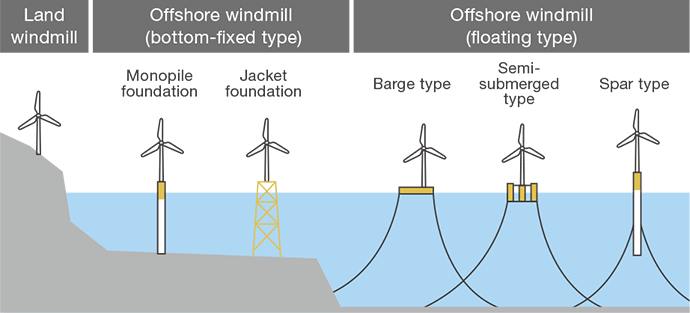

Introduction to offshore wind power generation

Wind power generation is renewable energy that utilizes the power of the wind to turn the blades of a windmill in order to generate electrical power. Offshore wind power generation is a new trend which uses windmills that are installed in the ocean. In Japan, development of land wind power generation has progressed, and suitable locations are becoming scarce. However because there are no surrounding obstructions in the ocean, the offshore winds in Japan are particularly strong, and there are many stable areas, the potential is believed to be extremely high. There are two types of offshore wind power generation: a bottom-fixed type where the generator is anchored to the seafloor, and a floating type which floats on the ocean. At present, construction is first proceeding of the bottom-fixed type that involves lower costs.

Reasons for becoming involved in offshore wind power generation

In 2017, members of Taiwan Power Company and other offshore wind power representatives came to Japan to investigate the construction of a supply chain, and visited Nippon Steel and Nippon Steel Engineering. Because at that time NST was in charge of arranging schedules and introducing related persons, this became the start of our initiatives for offshore wind power generation. Later, the largest steel manufacturer in Taiwan, China Steel Corporation, was planning to construct a new plant for plates to be used in jackets, and NST served as a pipeline between this manufacturer and Nippon Steel Engineering, which has expertise in this area. We learned much about offshore wind power generation, and have deployed what we learned to sales activities at related companies in Europe and Southeast Asia.

Roles of NST

NST, in cooperation with Nippon Steel Engineering, a company with extensive experience in jacket production, is participating in the construction of an offshore wind power supply chain that connects clients, general contractors, and processing companies. Our role in this project has been highly evaluated by related parties.

In the project to construct the new Ishikari Bay Shinko Offshore Wind Power Plant, which is the second largest offshore wind power plant in Japan, we contributed to construction of this power plant by delivering Nippon Steel jacket plates to Nippon Steel Engineering. This power plant completed construction in June 2024, and began operating in August.

Future prospects

In Japan, in addition to four projects in bay areas such as Ishikari Bay Shinko, a total of 35 development projects for bottom-fixed offshore power generation have been announced: ten in general sea areas (first round: 4, second round: 4, third round: 2), nine in promising areas, eight in upcoming areas, and eight other projects.

In June 2024, a sea area and contractor were decided for demonstration testing aimed at commercialization of floating-type offshore wind power generation. Because the floating type uses different materials and parts than the bottom-fixed type, such as the steel structures, mooring chains, and anchors, this is an opportunity for us to expand our business.

As a member of the Nippon Steel Group, NST will continue working to identify new investment prospects and acquire trade rights, construct a supply chain for offshore wind power generation, and promote the expansion of offshore wind power generation to contribute to the creation of a zero-carbon society.

Expanding sales of the pipes for piling and steel sheet piles that support national resilience

Constructing a sustainable society

Working to expand sales of the pipes for piling and steel sheet piles that support national resilience

Pipes for piling and steel sheet piles are important structural materials that support the foundations of structures such as buildings and bridges. They are concealed in ground or water after construction is completed, and are rarely visible, however they play an important role in supporting our everyday living. NST is focused on expanding sales of the pipes for piling and steel sheet piles that support national resilience.

Features and applications of pipes for piling and steel sheet piles

Pipes for piling feature high strength, high durability, and good workability. They are primarily used in the foundations of buildings and bridges, soil improvements such as reinforcing soft ground or preventing ground subsidence, and as countermeasures against earthquakes, floods, and other disasters. Steel sheet piles have superior water-blocking performance and good workability. They are used in projects such as river bulkheads, port quays, water cut-off walls, seismic reinforcement, disaster recovery, and temporary earth retaining works. They are also used in the water cut-off walls of regulating ponds and control reservoirs that serve as countermeasures to the torrential rains that are becoming increasingly severe.

National resilience

Source: Nippon Steel Group “National Resilience” solutions catalog

National resilience is an initiative that aims to make the country strong in the face of disasters. Based on the Basic Act for National Resilience that took effect in 2013, it is intended to learn lessons from past disasters and carry out advance countermeasures to prevent severe damage. Specifically, it includes forest maintenance, construction and reinforcement of a network of embankments and roads, countermeasures to aging infrastructure, and improvement of crowded urban areas. This is intended to reduce human and economic damage and achieve city planning where residents can continue to live after a disaster. National resilience is essential for the construction of a sustainable society, and is closely related to SDGs.

Roles of NST

The Structural Products Sales Department sells structural products including pipes for piling and steel sheet piles, and approximately 30% of them are used in projects contributing to national resilience. In response to requests from the construction companies who are our business partners, we provide estimates for the structural products prior to the bidding for the project, and function to coordinate delivery periods, delivery plans, and other elements. In particular in national resilience projects, pipes for piling and steel sheet piles are essential for projects such as regulating ponds and control reservoirs for flood countermeasures, reinforcement of aging infrastructure, and earthquake countermeasures, and we are focusing on expanding their sales.

Future prospects

In June 2023, in order to systematically and steadily carry out measures for national resilience, the Basic Act was revised to establish provisions related to the National Resilience Medium-Term Plan, as well as provisions related to the National Resilience Promotion Committee. National resilience is an initiative that is essential to the sustainable development of Japan. By providing materials and work methods that utilize the strength, stable quality, and environmentally friendly recycling performance that are characteristics of steel structures, we intend to contribute to infrastructure construction from the perspectives of disaster prevention and mitigation, and thereby contribute to the achievement of a sustainable society through national resilience.

System architecture as a standard construction method in the plant and warehouse architecture field

Low cost, short work period, high quality

System architecture helping to resolve client business issues

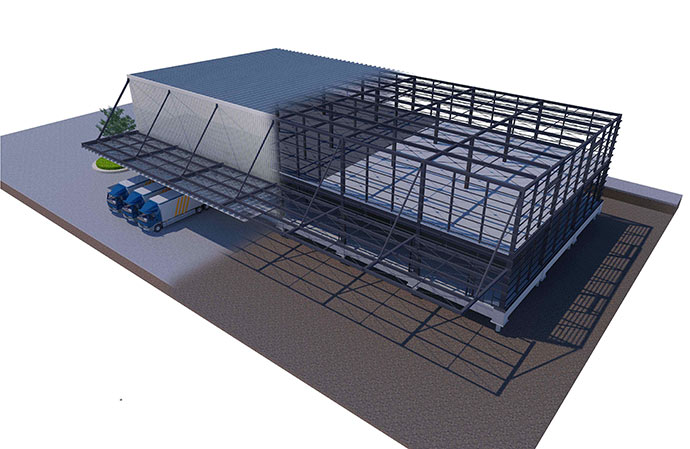

System architecture is primarily used for plants and warehouses. For plants, there is growing demand for investment in semiconductor-related construction and returning supply chain to Japan, while for warehouses, demand is growing for constructing sites as a countermeasure to the so-called “2024 problem” in logistics and for replacing buildings that have aged. At the same time, clients are facing issues including longer project periods resulting from shorter working hours and a labor shortage, as well as rising material prices. The construction industry has been slow to address SDGs, and system architecture is gaining attention as a solution.

What is system architecture?

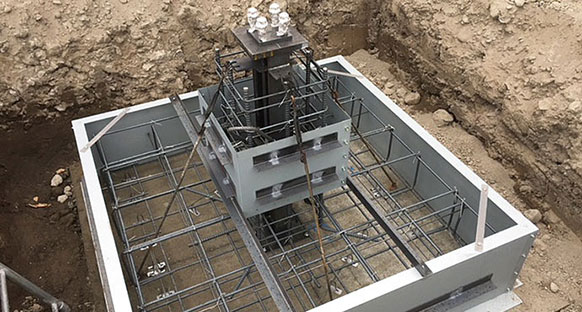

System architecture is a construction method that standardizes the height dimensions of building pillars and standardizes parts and materials, thereby increasing the percentage that can be produced at the plant in advance. This reduces unnecessary work and lack of uniformity in workplace work. When constructing a standard plant or warehouse, this method can reduce work periods and costs by around 25% compared to ordinary construction methods. This method also has a large number of advantages for improving carbon neutrality including a foundation system that reduces remaining earth and the amount of concrete used; modularization and standardization of parts and materials to reduce the amounts of steel material used, the amount of steel framework welding, and loss; and high transport efficiency resulting from the supply system composed of manufacturing bases for parts and materials located across Japan.

The reason why customers choose Nippon Steel Trading system architecture

There are several manufacturers providing system architecture, however NST is capable of constructing not only single-floor facilities but also two-story buildings, and the size of our product repertoire combining foundation and steel frame systems in many variations is unparalleled in the industry. In particular, our original foundation system that can be used with a wide range of ground conditions is one area that differentiates us from other companies. It can optimize the design, shorten work periods by greatly reducing the required labor for on-site work, and also reduce costs. As a specialized manufacturer with technologies and expertise that we have developed over our history of nearly a half-century, NST has constructed 4,500 facilities and currently constructs more than 200 a year. Repeat customers who use our products time and time again have spread to all parts of the country.

Future prospects

In the plant and warehouse architecture field, in the target market of facilities on the scale of 700 – 7,000 m2, the share of system architecture which includes our company’s systems is estimated to be more than 30%. System architecture is now becoming the standard construction method in this field. System architecture is based on the concepts of friendly to the environment and friendly to working people, and aims to create labor-saving buildings requiring low cost, short work periods, and high quality. It is a solution to the issues facing the construction industry, and also contributes to the development of local communities, and we will continue to grow this business in the future by continually pursuing “the optimal solutions for the client.”

Expanding sales of carbon fibers

Creating a decarbonized society with next-generation materials

Working to expand the use of carbon fibers

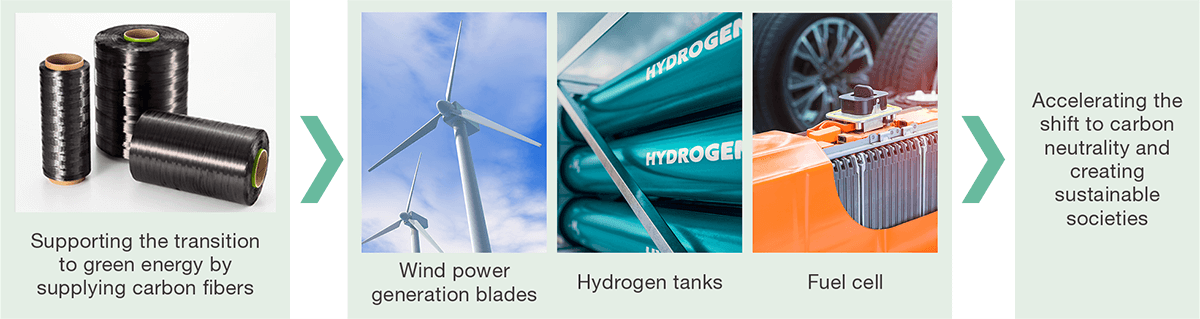

Because carbon fibers are lightweight, yet are extremely strong and have elasticity, they are used in a wide range of advanced technology fields. Because of these characteristics, they are used in the materials of products that make large contributions to creating a decarbonized society, such as wind power generation blades, hydrogen tanks, and fuel cells. The Industrial Supply & Infrastructure Division is expanding sales of carbon fibers in around 15 countries.

What are carbon fibers?

Carbon fibers are extremely fine fibers that are made of carbon atoms that have formed a crystalline structure. They are produced by carbonizing acrylic fibers or coal tar pitch (a byproduct of steel production) at high temperatures. Carbon fibers are lightweight and strong materials and are used in a wide range of products ranging from everyday products such as bicycles, golf clubs, tennis racquets, and other sports equipment to building reinforcements that ensure safety, as well as automobiles, aircraft, and satellites.

Primary applications of carbon fibers for creating a decarbonized society

Wind power generation blades

The installed capacity of wind power generation primarily as a source of clean energy is expanding rapidly centering on Europe, the U.S., China, and India. Blades are becoming larger in order to increase generating efficiency, and recently large blades with diameters of more than 140 m have been developed. When the size of a blade increases, it can capture larger amounts of wind, and as a result generating efficiency is higher. However at the same time, they also involve a higher risk of blades striking the supports and being damaged as a result of flexure due to the wind force while turning. Because the use of lightweight and high rigidity carbon fiber composite materials can prevent this risk, the amounts of carbon fibers used are growing year by year.

Hydrogen tanks

Decarbonization utilizing hydrogen is being carried out in countries around the world. The establishment of a supply chain for creating a hydrogen society has become an urgent issue, and demand for the pressure vessels necessary to store and transport hydrogen is growing. By wrapping a metal or plastic liner with carbon fibers, it is possible to design and manufacture pressure vessels that are lightweight and have high storage efficiency. As a result, the demand for pressure vessels using carbon fibers is growing every year.

Fuel cells

Fuel cells are a source of clean energy that generates electricity by a chemical reaction between hydrogen and oxygen, and are primarily installed in fuel cell vehicles (FCV). Carbon fibers in a paper form are used in the gas diffusion layers that are part of a fuel cell, and the superior conductivity, drainage performance, and gas permeability contribute to improving FCV fuel efficiency and extending the lifetimes. As the use of FCV become more widespread in the future, it is expected that demand for carbon fibers will grow even further.

Future prospects

The Industrial Supply & Infrastructure Division supplies high-quality carbon fibers for a wide range of applications, centering on wind power and hydrogen, supporting the transition to green energy at countries worldwide together with customers and suppliers. In the future, we will continue working to construct a new supply chain and strengthen the sales system in order to meet growing demand and needs, and contribute to the creation of sustainable societies around the world.

Business with Centaco Co., Ltd. (Thailand)

Solutions for growing health awareness and the protein crisis

Contributing to social needs with chicken raised on 100% vegetable protein

The Foodstuffs Division together with Centaco in Thailand have created, and are operating a commercial business for, the Botanical Chicken brand of chicken that is raised using feed composed 100% of vegetable protein and uses no fishmeal, fats, or other animal proteins.

About Centaco Co., Ltd.

Centaco is a leading company in the field of chicken farming, with an integrated production system that includes chicken raising, processing, and sales. Centaco is particular about food safety and quality, and its products are sold to customers both domestically and overseas. NST has maintained a business relationship with Centaco for more than 40 years, and has constructed a strong relationship of trust.

About Botanical Chicken

Botanical Chicken is an original NST brand product. Based on our desire to sell products that meet social needs such as ethical consumption, we launched a commercialization project jointly with Centaco in June 2023.

Feed made of 100% vegetable protein is used to raise the chickens, and a special NST production line has been constructed at Centaco for the processing process. Only products which pass inspection using an X-ray inspection system on loan from NST just prior to shipping are sold under the Botanical Chicken brand, allowing us to provide safe and reliable products.

Relationship with SDGs

Because chickens raised on feed made from vegetable protein are higher in protein and lower in fat (NST study) than chickens raised on feed made from animal protein, they can meet the recent demand for increasing health awareness, and are expected to help maintain and improve people’s health.

Furthermore, because it is not necessary to secure animals for the feed, we believe that this product can also help to resolve the “protein crisis” as demand for food meat grows as a result of global population growth and economic growth in developing countries, and as protein demand rises backed by factors such as the diversification of consumer needs.

Future prospects

Sales of Botanical Chicken have only just started, however we expect demand to grow in the future due to social needs such as increasing health awareness and the need to address the protein crisis. We also expect the amount of the product sold by NST to grow, and Centaco is planning to expand its plant in 2027. We have also begun creating products based on the same concept with a supplier in Brazil, and expect to begin sales to customers who prefer Brazilian chicken during the autumn or winter of 2024.

Even at volume retailers that prefer chicken produced in Japan, chicken produced overseas is gradually being introduced for sale. We will continue to promote sales of healthy, safe, and reliable chicken raised on 100% vegetable protein feed, and will contribute to “a recycling-oriented society and sustainable living” that is one NST materiality.

Operation of the original brand UNDYED®

Going beyond just being environmentally friendly

UNDYED® – Creating fashion that is never dyed

Based on the concept of manufacturing that allows users to enjoy the original color, texture, and comfort of natural materials, MN Inter-Fashion operates the original brand UNDYED® which uses organic cotton and minimizes the use of chemical dyes and other chemicals.

About UNDYED®

UNDYED® is a material label that produces products utilizing the original color and texture of natural materials, without the use of dyes or bleaches. It uses organic cotton to create undyed and unbleached products in order to minimize environmental impact. This allows users to enjoy the natural colors and textures, and allows us to provide sustainable fashion that is harmonized with nature.

Reason for becoming involved with UNDYED®

Because the textile industry uses and discharges large amounts of water in the process from cultivating the raw material cotton to producing the products, it is said to be an industry with a large environmental impact. The production of a single T-shirt requires more than two tons of water, and enough water to fill 2 million Olympic-sized swimming pools is used in the dyeing process every year.

As we consider sustainable manufacturing, we believe that avoiding the wasteful use of water and eliminating the dyeing process that uses chemical dyes and other chemicals will not only minimize the environmental impact but also provide safety and peace of mind to the people who wear the clothes and to the people and land where they are produced. This is the reason why we launched this brand.

Features of UNDYED®

UNDYED® uses the colored organic cotton that was first successfully cultivated by biologist and entomologist Sally Fox. Because the UNDYED® fabric uses no chemical dyes or other chemicals and is not bleached, it does not require fabric softener, and focuses on the original texture of the raw materials. For this reason, although the shrinkage rate varies depending on the color, cotton scraps may remain, and nonuniformity of the treads may occur, we have carried out this initiative together with customers who sympathize with this concept.

The organic cotton used in UNDYED® comes in three colors: brown, green, and white. By using a method known as iron mordanting, we succeeded in producing khaki and heather grey colors, expanding the color variations and expanding the range of fashion applications.

Future prospects

This initiative was initially started from the perspectives of SDGs and sustainability, however now one of its goals is to have people recognize and share the understanding that fashion can be enjoyed as a style even when it is not dyed.

At present we are focusing on activities in Japan, and are proceeding as the number of customers who sympathize with this concept steadily grows. In the future, we will incorporate even more diverse materials and designs, and expand the potential of sustainable fashion. We will aim to provide better products that are not only environmentally friendly but also strengthen the relationships of cooperation with local communities and producers.