Contributing to a Decarbonized Society and Environmental Conservation

Expanding sales of water electrolyzer component stacks

Aiming for the realization of a decarbonized society

Working to expand the use of green hydrogen

In order to capture the demand for green hydrogen that is expected to grow worldwide in the future on the path to achieving carbon neutrality, in September 2022 NST invested in the Norwegian electrolyzer manufacturer HYSTAR AS (hereafter referred to as “HYSTAR”).

What is green hydrogen?

Hydrogen is classified into three types: gray, blue, and green. Green hydrogen is hydrogen that is produced by water electrolysis using renewable energy, and can be produced without emitting CO2. At present, development is proceeding centered on Europe and the United States. In Europe where environmental awareness is high, the European Commission in July 2020 announced “A hydrogen strategy for a climate-neutral Europe” and identified the promotion of green hydrogen. The use of renewable energy is already expanding in the EU, and introduction should be easy. In addition to these reasons, the fact that hydrogen is seen as an effective alternative which can reduce dependence on Russian natural gas has also boosted the promotion of green hydrogen. Reducing dependence on Russia became a critical issue following the Ukraine crisis. Full-scale development is underway, and the pace of expanding use is accelerating.

Functions that NST aims to make use of

HYSTAR is a company that develops, manufactures, and sells water electrolyzers for production of green hydrogen. The stack is the core component of a water electrolyzer, and the company produces the stack itself. Other ancillary equipment is ordered from outside the company. HYSTAR engages in the actual manufacture and sales of the water electrolyzers. As a specific measure for sales of high-performance materials, which is one element of our growth strategy, NST has entered the hydrogen-related business through its investment in HYSTAR, and intends to capture the following growth opportunities.

- 1.Priority deliveries of titanium, stainless steel, and other materials and parts when HYSTAR procures materials

- 2.Creation of new business related to hydrogen through collaboration with HYSTAR when selling HYSTAR water electrolyzer equipment in Asia

We will focus on the supply of materials for stacks and work to expand the use of green hydrogen through our business, aiming to contribute to the realization of a decarbonized society.

Source: From the HYSTAR website

Investment in Bio-carbon (Black Pellets)

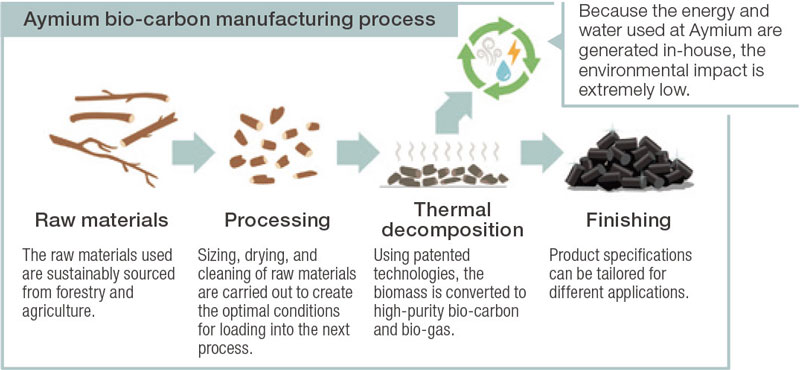

Nippon Steel Trading Americas, Inc. (hereafter, “NSTA”) is a subsidiary of NST in the United States. In March 2022, NSTA accepted an allocation of newly issued shares from NCT Holdco, LLC (hereafter, “Aymium”), a company which manufactures and sells bio-carbon (black pellets).

Reason for choosing Aymium as a partner

Aymium is a strong start-up venture that manufactures high-quality bio-carbon using its own original patented technologies. In the U.S. state of Michigan, it is currently operating the largest bio-carbon production plant in North America, where it produces primarily black pellets.

As a result of its original technologies, Aymium products feature higher heat values and higher levels of fixed carbon than ordinary black pellets. In addition, because the handling properties allow these pellets to be used as a substitute for ordinary coal products, it is not necessary to change equipment specifications in order to use them. Aymium has a strong foundation in both production using its original patented technologies and sustainability, and we concluded that it is a partner whom we can work with as the NST Group works to operate a zero-carbon business in the future.

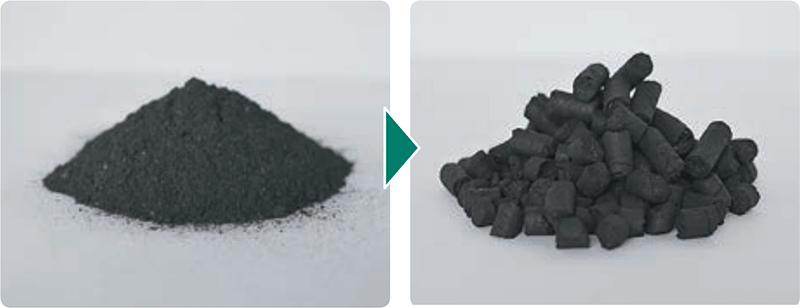

Black pellets

Black pellets are created from wood biomass raw material, which is carbonized by torrefaction under conditions that are shut-off from air and then formed into pellet shapes. Black pellets are positioned as carbon neutral products.

Aymium has acquired CoC* certification from an international forestry certification agency, and strictly manages its supply chain, including its raw material suppliers, and has taken complete action so that its products are fully compliant with laws and sustainable.

- *Acronym for “Chain of Custody.” This is a system for tracking raw material certification information to verify that it has been appropriately processed and distributed at all stages until the product reaches the consumer when using wood material or recycled material that has received forestry management certification.

Expected benefits for the environment

Black pellets are made by semi-carbonizing pulverized, dried, and torrefied wood materials. In addition to their use as a substitute for ordinary coal in electricity production, they can also be used as a carburizer, sintering fuel, PCI fuel, or other materials in steelmaking applications. As a result, they are expected to be an efficient and practical means of reducing CO2 emissions by steelmakers, power companies, and others aiming for carbon neutrality.

In particular the Aymium black pellets enable the production of high heat value products (approximately 50% higher heat value compared with low-temperature torrefaction), and allow reductions in various costs (especially transport costs) per unit of heat value. Another advantage is that the high-calorie biomass collected following the high-temperature torrefaction process can be reused in raw material drying and thermal decomposition processes, reducing environmental impacts.

Future prospects

At present, Aymium is constructing new U.S. plants located in California and on the Pacific Northwest coast. The funds acquired from this capital increase will be utilized for this construction. The company will continue to expand production capacity in the west coast and the southeast, where ample supplies of wood biomass are available. In addition to sales in the U.S., it also plans to supply products to consumers in Japan, Asia, and Europe.

The high-quality black pellets of this company can be used as a power generating fuel and as a steelmaking raw material. By becoming actively involved in sales activities, the NST Group will contribute to realizing a zero-carbon society.

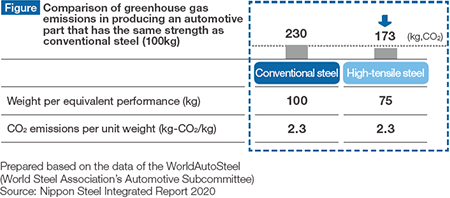

Sales of Eco-Products

Steel is a material that has a very low environmental impact and can be recycled infinitely when its value is repeatedly used throughout its life cycle. In addition to expanding the sales of steel, the Steel Division also focuses on the sales of eco-products, including the following:

| Sale of High-Tensile Steel Sheets for Automobiles and Aluminum-Plated Steel Plates for Hot Stamps | Ensure safety in case of a vehicle crash, reduce the vehicle weight, and improve fuel economy. → Contribute to CO2 emissions reduction.

|

|---|---|

| Sale of HRX19 Stainless Steel for High-Pressure Hydrogen Environments | Achieve high safety, compactness and longer product life. Have anti-hydrogen brittle properties. Use in highpressure areas of commercial-use hydrogen stations. → Contribute to infrastructure development for the realization of the hydrogen society. |

| Sales of NS Eco-Pile | Steel pipe piles for civil engineering and construction that are driven into the ground by rotating vanes. → Achieve low vibration, low noise, and low earth removal, as well as high support and high durability. |

| Sales of SuperDyma High-Durability Plated Steel Plate | High corrosion resistance and anti-rust properties that eliminate the need for coating after processing. → Contribute to the reduction of life cycle costs by shortening the construction period and expanding service life. |

Meeting the Needs of the New Era

In the Industrial Supply & Infrastructure Division, we are focusing on expanding sales of aluminum and carbon fibers. In response to the needs of new multi-material products, we are proposing new materials and building supply chains that use our domestic and overseas sales networks.

Efforts to Generate Solar Power from Water

Floating Solar Power Generation System

In April 2020, NST, Environmental-Resources Development Consultant, Sekisui Plastics Industries, Ltd., and Smart Energy Co., Ltd. established a joint venture company called “Floating Solar GK”, which sells floating solar power generation systems. These systems can increase the supply of renewable energy.

NST is contributing to the construction of floating solar power generation systems by supplying surface-treated plated steel plates with high strength and high corrosion resistance for use in corner plates, floor surfaces, and platforms in sea or lake areas. Use of steel has made Suijo Solar’s system more robust than a system made of conventional plastic materials and more resilient to a typhoon or other disaster.

The floating solar power generation system makes effective use of water space, such as ponds and lakes. Compared to the ground-based system, construction costs for land development and (when applicable) fixed asset taxes are not required, and costs are reduced thereby, and water-cooled effects enable high-efficiency power generation. Because of these benefits, the floating solar power generation systems have attracted attention in recent years.

In Japan there are approximately 210,000 reservoir of water, which may potentially be used in the future. According to the New Energy and Industrial Technology Organization’s (NEDO) white paper on renewable energy technologies, the potential for the introduction of solar power generation using such freshwater sites is estimated to be approximately 38,800 MW. Currently, only about 1% of that estimated power generation has been introduced and construction of more systems is expected in the future.

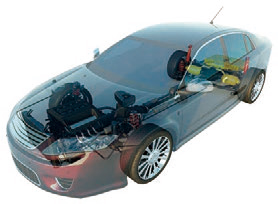

Initiatives in the Automotive Sector

Efforts toward carbon neutrality are accelerating worldwide, regulations on the sale of gasoline powered vehicles and announcements by automobile manufacturers of discontinuation of making such vehicles have been made, and the worldwide ratio of xEV (electric vehicle or plug-in hybrid vehicle) in automobile sales is expected to increase rapidly.

We are actively working to expand our business in the fields of drive motors and batteries, which are the main components of xEV.

In the field of drive motors, while we sell high-performance electrical steel sheets, which are materials for motor cores, we are more focused on technology development to improve performance.

Lithium-ion batteries are currently the dominant battery, but the development of next-generation batteries is progressing with the aim of higher performance and safety. We will continue to capture demand while understanding these technological innovations.

In addition, as a trend toward carbon neutralization in the automotive sector, the weight reduction of the bodies is an important issue for both engine-driven cars and EVs. Use of advanced steel materials to reduce weight and needs of multimaterials will continue to grow.

There are also movements to consider material selection from the perspective of LCA (Life Cycle Assessment), which takes into account the entire product life - from manufacturing of materials, parts, and bodies, to operation, disposal, and recycling of a vehicle. We are carefully monitoring and adapting to these developments.

Efforts Toward a Hydrogen Society

NST is taking initiatives in each aspect of hydrogen production, storage and transportation, and utilization.

We are getting involved in transaction of components of water electrolytic devices on the production side, and of tanks for piping and storage at hydrogen stations on the storage and transportation side, as well as of separator materials for FC (fuel cells) stacks for FCV (fuel cell vehicle) on the utilization side.

We are also actively promoting business development, in cooperation with manufacturers and related companies, targeting 1) products to be adopted for hydrogen-fueled vessels, railways and others, which are expected to be in widespread use by around 2030, 2) hydrogen power generation in the industrial sector, 3) the process of producing hydrogen reduction steel, and 4) a type of fuel cells for the home sector, among others. In the future, we will strengthen our functions in order to participate in the hydrogen strategy as a national project.