Programs for food safety and reliability

The Foodstuffs Division recognizes that providing safe and reliable foods is an issue of the greatest importance, and is strengthening safety management for handling of food products throughout the Group, centered on the Food Quality Assurance Department.

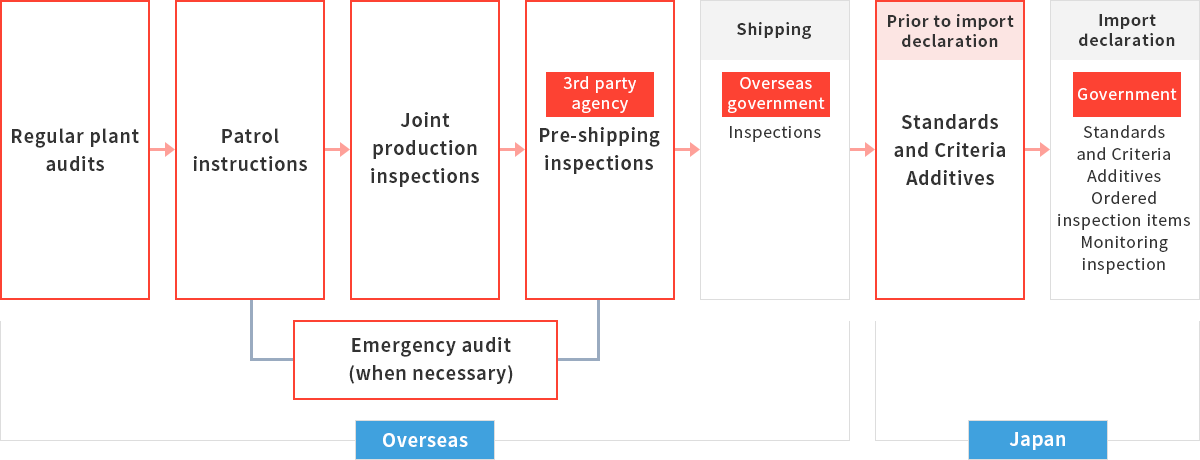

System for supply of safe and reliable processed food products

For processed foods, we carry out complete sanitation control through means including selection of reliable overseas cooperating plants, regular plant audits, patrol instruction, and government inspections. (The red boxes indicates inspections that are conducted by our company.)

Checks and quality inspections for reliable raw materials

- 1.Safety checks of raw materials by means of farm inspections and positive lists

- 2.Obtaining standards and inspection reports for processed raw materials, and conducting safety checks

- 3.Pre-export inspections and regular raw material inspections conducted by a Japanese-owned China inspection agency in which NST has invested

- 4.Ensuring traceability

Examples of inspection items and details

| Time of delivery from raw material manufacturer | Food production license / Standards / Inspection reports |

|---|---|

| Time of raw material receiving | Microorganisms / Residual agrochemicals / Residual animal drugs / Sensory inspection |

| Regular plant audits | Workers / Sanitation / Quality control by management / Raw materials and packaging materials / Production process / Packaging and labeling / Shipping, distribution, and complaints / Buildings and equipment / Safety management and sanitation awareness |

| Patrol instructions | Instruction for resolving problems at times of regular plant audits |

| Emergency audits | Food sanitation / Compliance / Food defense |

| Joint production inspections | Raw materials used / Nonconforming raw materials / Auxiliary materials / HACCP < CCP (Critical Control Points) / Metal and X-ray detectors / Foreign substance exclusion |

| Pre-shipping inspections | Animal drugs / Residual agrochemicals / Heavy metals / Standards (microorganisms, additives) |

Renovation of notification system

The Foodstuffs Division has created a notification system for central management of complaints (such as foreign substances) from consumers (including cases when complaints were received via a customer company).

Appropriate batch labeling

- 1.Check for batch labeling that conforms to food-related laws

- 2.Check and incident prevention related to allergens in raw materials

- 3.Nutritional analysis and nutritional labeling

Internal training and complete implementation for sanitation and safety

- 1.Number of registered imported food sanitation supervisors: 57 (as of December 2019)

- 2.Holding of regular internal seminars by external instructors