Safety, Quality Control, Compliance

Among the various risks, NST focuses its attention on further strengthening company-wide efforts concerning risks related to safety, quality, and compliance. It includes cooperative efforts with the business and functional divisions to identify the critical risks that could have a serious impact on management, and to examine and implement measures to eradicate them.

Initiatives for Safety

Steel Division (Technical Support & Safety Management Department)

The Steel Division aims to eliminate the danger of serious disasters and prevent disasters and accidents causing lost worktime. It is carrying out independent safety activities focusing on the two priority measures listed at right.

- Priority measures

-

- 1.Complete safety initiatives backed by rules

- (1)Complete safety initiatives

- Fully prepare work standards free of omissions and unclear expressions.

- Ensure rule compliance through the use of monitoring cameras.

- Communicate work procedures and implement measures, etc. through holding of reliable TBM(Tool Box Meetings).

- (2)Redevelopment of safety awareness using training and other means

- Reliably carry out exercises, risk simulation training, case studies of disasters at similar organizations, etc.

- Carry out key training programs for new employees and transfers, and continue conducting reliable follow-up monitoring.

- Further develop safety awareness using DVDs, VR (Virtual Reality), and the Web.

- (1)Complete safety initiatives

- 2.Reliable compliance with new laws and regulations

- Compliance with adoption of autonomous management for chemical substances, etc.

- 1.Complete safety initiatives backed by rules

Industrial Supply & Infrastructure Division (Industrial Supply & Infrastructure Planning Department)

- Priority measures

-

- 1.Follow-up by checking the progress of the voluntary safety audit

- Support was provided to enable each manufacturing site to establish and further strengthen a system in which it can continue its own efforts to identify and resolve improvement issues based on independent safety audits.

- 2.Examples at Group companies Nippon Steel Trading Metals Co., Ltd.: Initiatives for work safety

- Holding monthly meetings of the Safety and Health Committee

- Continually setting new records for zero accidents. Target: 1,250 days (expected to be achieved on January 10, 2024)

- 1.Follow-up by checking the progress of the voluntary safety audit

The Safety Conference was conducted in May 2023, and an awards ceremony was held for Group companies with a superior record of safety during fiscal 2022. Safety is the foundation of corporate operations, and is positioned as an issue of the highest priority in the NST Group. We will continue to reinforce a range of initiatives aimed at improving the quality of our safety activities.

President Tsurumi of Igeta Sunrise Pipe

Corporation(right), receiving the award on

behalf of the three companies

(left: President Nakamura)

- Companies achieving a continuous three-year record of zero accidents

-

- Igeta Sunrise Pipe Corporation

- Shenzhen NS Steel Centre Co., Ltd.

- Dongguan Tetsuwa Metals Co., Ltd.

- Safety activity contribution award

(companies recognized as making a special contribution to safety activities) -

- Tokyo Seisen Co., Ltd. (conduct of efficient and effective safety activities utilizing Cloud services)

- Priority measure activity award

(companies implementing activities that are a model for the entire Group) -

- Nippon Steel Trading Metals Co., Ltd.

- Shenzhen NS Steel Centre Co., Ltd.

- Shanghai Nippon Steel Trading Automotive Parts Co., Ltd.

- Bangkok Eastern Coil Center Co., Ltd.

Initiatives for Quality Control

DX Promotion Department

In quality control, operations requiring manual operation cannot be zero risk. In July 2020, NST established the DX Promotion Department under the direct control of the President to address the challenge of eliminating this quality risk by digitalizing operations across all manufacturers, distributors, and customers.

- 1.“N-SCM” Integrated inventory management system

- Automation of inventory control in repeating transaction fields in order to produce faster responses to changes in conditions, and to prevent shipping problems caused by missing materials or wrong materials.

- 2.“SPOD” Improved order entry system

- Standardization of order placement operations and strengthening of the check functions to improve accuracy and efficiency, and to eliminate human errors.

- 3.“EXCS®” New coil center system

- Updating and consolidating the core business management systems at NST subsidiary coil centers.

- *(N-SCM and SPOD began operation in the second half of FY 2021. We are continuing to expand the functions and increase the number of product categories. The EXCS® infrastructure was launched in the first half of FY2023. Since then, we have been expanding the functions and increasing the number of sites as a medium- to long-term initiative.)

Steel Division (Technical Support & Safety Management Department)

The Division has designated the period up to system implementation by the DX Promotion Department as the priority management period, and is reducing the numbers of check items and carrying out thorough double- and triple-checking.

- Priority measures

-

- 1.Double-checking through monitoring of the sales department’s order entry operations

- Confirm and optimize the double-checking conditions, and apply them to work standards, in order entry and processing order operations.

- Create and maintain order data masters.

- 2.Support for improvement of priority management items in affiliated companies

- Utilize bar coding, and conduct automatic transmission and judgment of measured values with the aim of reducing reliance on human resources.

- 3.Activities to support sales and affiliated companies

- 1.Double-checking through monitoring of the sales department’s order entry operations

Industrial Supply & Infrastructure Division (Industrial Supply & Infrastructure Planning Department)

- Priority measures

-

- 1.Thorough guidance and continuous monitoring of key suppliers in the Mobility Business Department and the Functional Materials Department

- 2.Establishment of a technology quality assurance manager in the division, carrying out quality action for car manufacturers and other customers, and constructing a quality management system for each supplier

Foodstuffs Division (Food Quality Assurance Department)

In the Food Quality Assurance Department, we are carrying out measures against foreign matter inclusion (including allergens) in processed foods.

- Priority measures

-

- 1.Stringent selection of processing plants, and thorough analysis and tracing of ingredients, including sub-materials

- 2.Strengthening of recall training on the production side and study of recall training in cooperation with sales partners

- 3.Engagement of insurance to insure against damages in cases when responsibility is not clear

- 4.Expansion of support for human resources development (further improvement of safety measures through the use of highly skilled employees)

Initiatives for Compliance

Basic approach to internal control systems

NST has clarified its basic attitude to emphasize compliance in accordance with the Corporate Philosophy, Management Principles, and Employee Code of Conduct. NST implements and operates internal control appropriately, further strengthens its corporate governance, endeavors to ensure “compliance with laws and ordinances,” “reliability of financial reporting,” and “effectiveness and efficiency of operations,” and aims to improve them continuously.

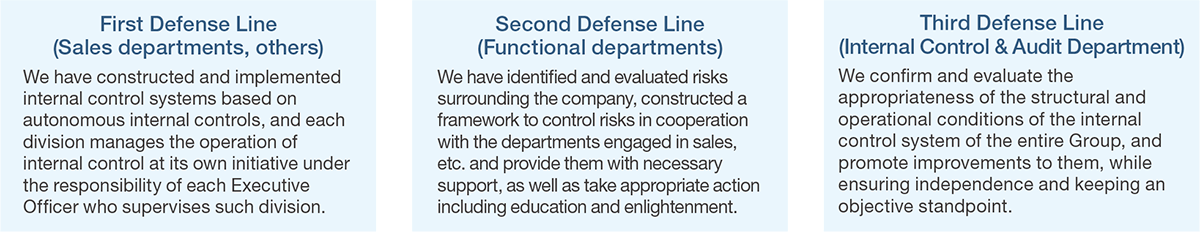

1. Internal control in business execution (three defense lines)

NST has constructed and maintains an internal control system based on three defense lines: the first defense line comprised of departments engaged in sales, etc.; the second defense line including functional departments, mainly comprised of the Corporate Planning & Administration Division and its departments as well as each sales planning department; and the third defense line comprised of departments engaged in internal controls and auditing.

2. NST Group’s internal controls systems

NST and each subsidiary shall establish internal regulations to ensure the appropriateness of business in accordance with the Corporate Philosophy, Management Principles and Employee Code of Conduct, and hold business strategy in common based on the business characteristics of each division and subsidiary. Thus, NST and each subsidiary shall operate as a single group. Each Executive Director, Executive Officer and general manager in NST and the directors of each subsidiary shall have employees fully understand the Corporate Philosophy, Management Principles, Employee Code of Conduct and regulations, and perform self-checks and monitoring. The department in charge of the management of each subsidiary shall operate the subsidiary appropriately in accordance with the “Subsidiary Management Regulations,” the “Subsidiary Management Standards,” etc., under the responsibility of the Executive Officer who supervises such department. NST shall dispatch its Executive Directors, Executive Officers or employees to subsidiaries as Directors or Audit & Supervisory Board Members in case of necessity, and ensure the appropriateness of business execution. The department(s) engaged in internal controls and auditing shall cooperate with the department(s) engaged in functions, instruct and support the internal controls system of NST and its subsidiaries, hold information with the subsidiary in common, and aim to fulfill the requirements of internal controls.

Internal reporting system (Compliance Hotline)

NST has established and operates the Compliance Hotline for employees and others at NST and its subsidiaries as a contact for internal reporting and consultations related to risks in the conduct of our operations. It protects confidentiality for reporting, and protects whistleblowers from retaliation. This contact system was established based on contracting to an outside party so that whistleblowers can report and consult with confidence, and we are working to expand and continually improve it.